In a moment of serendipity, Bamboo Bike Studio moved into my neighborhood (the Tenderloin) and I started feeling bike lust. It doesn’t sell finished bikes, but instead offers DIY kits or workshops to build your own bike from scratch under the guidance of the staff.

Feeling like I had wasted too much of my life in a state of moronic bikelessness, I decided it was time to learn about the Zen of bike building. And not just any bike, but one made out of grass — yes, grass. So I signed up to build a bike with Justin Aguinaldo, one of three cofounders of the Bamboo Bike Studio.

Justin loves bamboo bicycles because they are extremely resilient and durable, as well as lightweight. Exposed to the elements, they can last for years. They’re apparently also the most comfortable to ride, absorbing shock and dampening vibration better than steel or aluminum (he should know after riding every kind of bike imaginable as a former bike messenger and racer).

The Bamboo Bike Studio uses “iron bamboo” from the Yucatan region in Mexico because it was found to be the strongest after testing many kinds from various origins. Justin explains that bamboo is one of the fastest-growing grasses in the world — up to 39 inches per day — so it can be harvested often, every one to six years. It is also one of the most versatile raw materials, used through the millennia for the construction of houses, boats and bridges, bows and arrows, furniture and clothing, musical instruments and pipes.

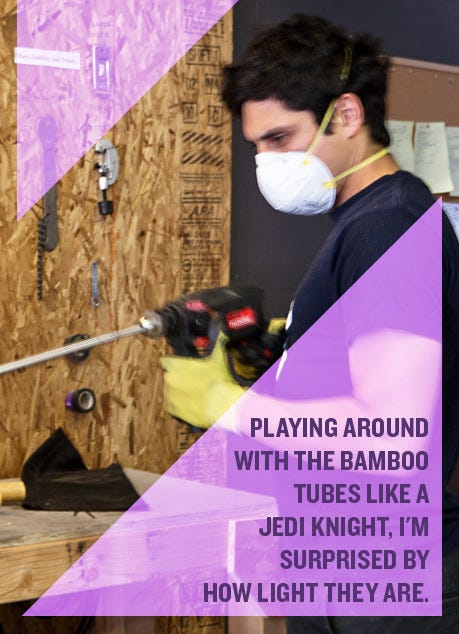

Playing around with the bamboo tubes like a Jedi knight, I’m surprised by how light they are, making it hard to believe that in a couple of days they’ll become a bike. Justin interrupts my goofing around to take the tubes and carve out their insides with a long drill, making him look a bit like a nightmarish dentist.

After roughing and beveling the ends of the now completely hollow bamboo tubes, we glue them to the metal and balsa wood cores and then to the dropouts on the other end. While we’re going to town with the hot glue gun, Justin tells me about the origins of the Bamboo Bike Studio, an offshoot of a nonprofit project aimed at reducing poverty in rural Africa.

While living in New York City, Justin got involved as a volunteer with the Bamboo Bike Project at Columbia University’s Earth Institute. The group wanted to design an affordable, reliable, and multipurpose bike for rural sub-Saharan Africa using widely available native bamboo. Bikes are in high demand there, mainly to transport goods to the market, but also as shared taxis, or simply to get around. But bikes found in Africa are almost exclusively made in China, of poor quality, and not well suited for the conditions of tropical, rural regions.

Justin had a day job at a bike messenger cooperative he had cofounded, so he worked in the evenings making bamboo bike prototypes for Africa. The initial goal of the project was to establish bicycle production facilities in Ghana using locally sourced bamboo managed wholly by local investors and staffed by local builders. Unlike many projects in Africa, it was designed to be profitable and sustainable on a local scale, which is pretty cool. After a few years working on it, the first factory opened last January in central Ghana in the town of Kumasi. Another one may open soon in Kenya.

After a while the group needed a larger space to build and test the different bikes that were being developed, and ended up renting a space in Brooklyn. As more and more people dropped by inquiring about the bikes, that space eventually became the first Bamboo Bike Studio and opened to the public. It has since become a mobile unit that tours the country to teach bike building wherever there’s demand. A studio recently opened in Toronto, and the San Francisco location has become “Bamboo HQ” — managed by Justin.

Workshops, which are in high demand, are scheduled almost every weekend, and so far over 400 bamboo bikes have already been built. The workshops are quite intensive — it takes around 30 hours for someone like me (who isn’t the handiest of human beings) to build a bike from scratch. The process is quite simple but it requires precision and dedication.

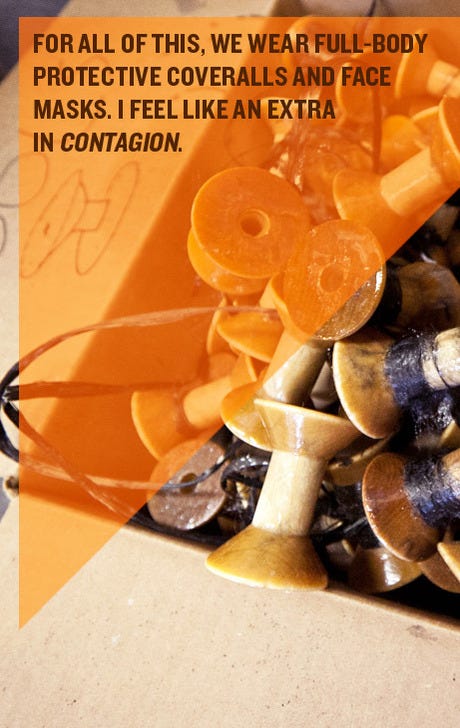

Justin has come up with a system of wrapping the joints first with resin-saturated fiberglass, and then with carbon fiber to make composite lugs around the bamboo frame members. Once the resin has cured, the wrapping is carefully filed and polished. For all of this, we wear full-body protective coveralls and face masks. I feel like an extra in Contagion .

Justin has built so many bikes over the years that he makes it seem like child’s play, but my fiber yarn is constantly getting tangled and I’m making a mess with the resin sticking all over my hair. Although I have to be constantly corrected (er, rescued), Justin is very patient and encouraging.

I ask Justin if he ever has any free time, and he laughs and says that those at Bamboo Bike Studio are “idealist workaholics” who have turned their passion into their life mission. That’s why on any given day I encountered people dropping by the studio to ask bike-related questions or do some work on their bikes while Justin happily shares his vast knowledge.

After hours of intense labor, involving many pairs of gloves and a sore shoulder, I feel like I’ve had a taste of the amount of effort these guys put in to designing the bikes. The three cofounders have a deep love for bicycles and firmly believe they can empower people to be more self-sufficient. That’s why they work night and day to constantly improve the bike-building process to make it safer, more efficient, and accessible for everyone.

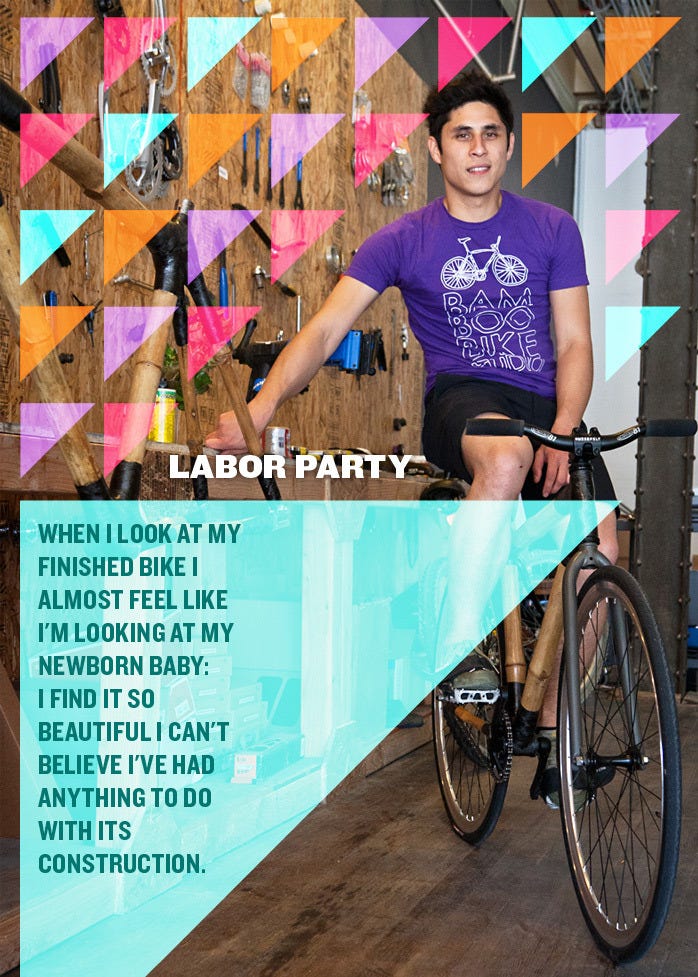

My bike is almost ready. I only need to choose the components to finish it off. Justin, who loves to do tricks, has made a fixed-gear set up for himself. My bike is more standard, with gears, regular wheels, and a cushy “girl’s seat.”

When I look at my finished bike I almost feel like I’m looking at my newborn baby: I find it so beautiful I can’t believe I’ve had anything to do with its construction. It’s not a coincidence that Bamboo Bike Studio’s motto is “the best bike is the one you make yourself.”

If you want to make your own bamboo bike and you already have some building knowledge, you can purchase a kit to make it at home. The kits start at $496 for just the frame (you can add your own components at home or from your local shop), and it comes with everything you need to build a bamboo bike frame, minus a few simple items that you can get at your hardware store or from your toolbox.

You can also sign up for one of the intensive weekend workshops at the Bamboo Bike Studio. They’ll supply you with all of the tools and materials you’ll need, along with help from an experienced builder. Starting at $700 for the Coaster, you’ll get to ride away on a bike that you made with your own blood, sweat, and tears.

BBamboo Bike Studio also permits anyone in the neighborhood to drop in and use the tools for free. The guys also offer classes for bike mechanics and paid repairs if your DIY skills are a little SOL. Find out more on their website or become friends with them on Facebook.

Thanks to Kelly Gregory for modelling her bamboo bike for this story.